03/2023

Multi-scalar modelling for robotic prefabrication

What are the potential benefits and challenges of implementing open collaborative multi-scalar modelling and planning strategies, considering robotic fabrication, in the Architecture, Engineering, and Construction (AEC) industry?

Georg Lobe

Diploma in Architecture

E259-2 Tragwerksplanung und Ingenieurholzbau

Supervisor: Zeynep Aksöz Balzar

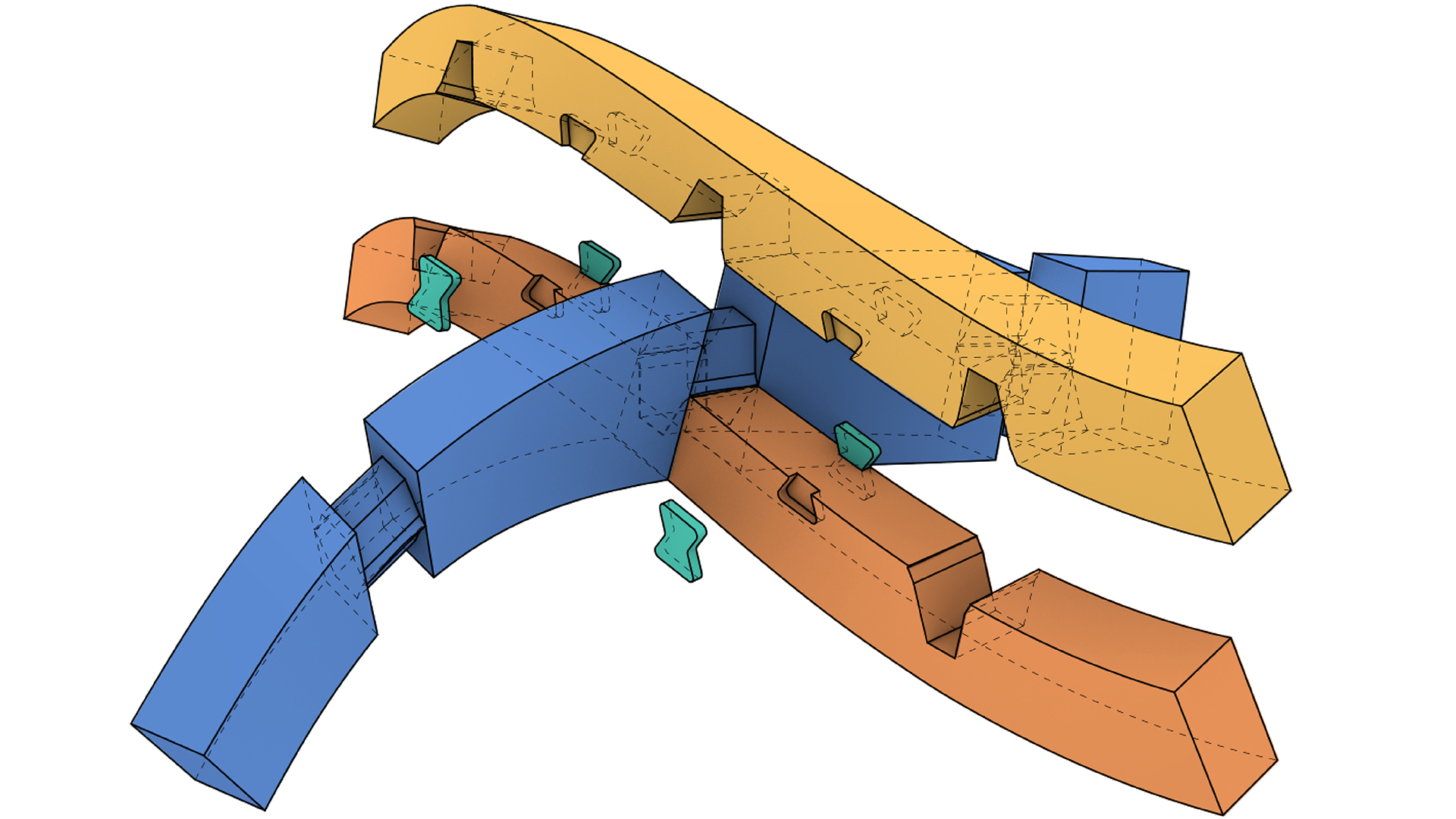

The thesis investigates current practices and developments in open collaborative multi-scalar modelling and planning strategies for the Architecture, Engineering and Construction (AEC) industry, with a focus on robotic fabrication. It aims to address the repetitive nature of modelling tasks in the building sector, which leads to data loss, extended development processes, and increased costs. The research develops a prototypical workflow for generating a free-form grid-shell using doubly curved glulam beams.

The proposed approach emphasises collaboration and precision throughout the project’s stages, from conception to fabrication. By utilising a parametric environment, connected multi-scalar modelling enables seamless integration between design and robotic fabrication. The use of web-based services ensures accessibility of data for all stakeholders, fostering collaboration and dataflow across platforms and software packages.

The workflow incorporates multiple models of different levels of detail (LOD) that dynamically react to changing parameters. Cloud services support independent accessibility and on-demand computational power for qualified personnel. Recomputation and updates can be invoked downstream in the dataflow as needed, enhancing efficiency and accuracy.

The thesis evaluates the usability of existing tools and identifies opportunities for feedback loops within the workflow. It also assesses information requirements and potential for robotic fabrication and control.

Overall, the thesis aims to overcome the limitations of current modelling strategies in the building sector by introducing an open and collaborative approach. By combining precision, speed, and multi-scalar modelling, it seeks to streamline development processes and accommodate the increasing complexity and volume of construction projects. The integration of robotic fabrication further enhances efficiency and collaboration in the AEC industry.

The thesis investigates current practices and developments in open collaborative multi-scalar modelling and planning strategies for the Architecture, Engineering and Construction (AEC) industry, with a focus on robotic fabrication. It aims to address the repetitive nature of modelling tasks in the building sector, which leads to data loss, extended development processes, and increased costs. The research develops a prototypical workflow for generating a free-form grid-shell using doubly curved glulam beams.

The proposed approach emphasises collaboration and precision throughout the project’s stages, from conception to fabrication. By utilising a parametric environment, connected multi-scalar modelling enables seamless integration between design and robotic fabrication. The use of web-based services ensures accessibility of data for all stakeholders, fostering collaboration and dataflow across platforms and software packages.

The workflow incorporates multiple models of different levels of detail (LOD) that dynamically react to changing parameters. Cloud services support independent accessibility and on-demand computational power for qualified personnel. Recomputation and updates can be invoked downstream in the dataflow as needed, enhancing efficiency and accuracy.

The thesis evaluates the usability of existing tools and identifies opportunities for feedback loops within the workflow. It also assesses information requirements and potential for robotic fabrication and control.

Overall, the thesis aims to overcome the limitations of current modelling strategies in the building sector by introducing an open and collaborative approach. By combining precision, speed, and multi-scalar modelling, it seeks to streamline development processes and accommodate the increasing complexity and volume of construction projects. The integration of robotic fabrication further enhances efficiency and collaboration in the AEC industry.

Diploma in Architecture

E259-2 Tragwerksplanung und Ingenieurholzbau

Supervisor: Zeynep Aksöz Balzar